Functional study and reliability analysis of an automatic machine for the deposition of photovoltaic cells

Brief

Optimisation of the company’s design process based on improved integration of the various teams (mechanical, electrical, electronic, IT) and on an integrated design of the machines starting from system specifications that propagate down to the lowest level component (a “Systems Engineering” approach).

Reconstruction of the functional model for reverse engineering, functional and reliability analysis of an automatic machine for the screen printing of photovoltaic cells.

Project challenge

- To provide the client with a “Systems Engineering” approach based on a greater collaboration between design teams and that starts from specifications of the complete system, which, in turn, propagate to the lower level components;

- Develop a functional model of a real machine based on incomplete technical documentation;

- Develop a reliability analysis of a real machine in the absence of component failure data.

Solution

NIER held dedicated meetings wherein an operational method was transferred to the client. This method was continuously applied to increase corporate awareness and monitor activities in an objective and systematic manner.

This method was then implemented in a case study that involved the functional and reliability analysis of an automatic machine for the screen printing of photovoltaic cells.

To achieve this purpose, starting from the client’s data and with a typical reverse engineering approach, NIER reconstructed the machine’s work flow and identified the operating modes of its components, thus achieving a complete functional analysis.

Finally, an FMEA was developed to quantify the frequency of occurrence of the identified failures.

Execution phases

Study and critical analysis of the documentation provided in order to assess its completeness and consistency (e.g. between BOM and assembly drawings)

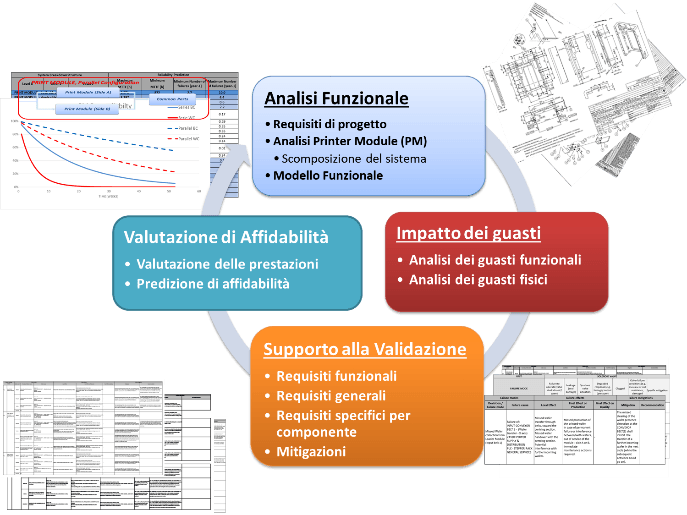

Functional analysis

- Definition of project requirements;

- Reorganisation of machine components into physical and functional assembly grouping;

- Process modelling and definition of each individual activity carried out by the process machine (individual machining) or service machine (position verification);

- Definition of a component vs. activity correlation matrix;

Elicitation of machine functional and physical failures; methods, causes and effects were identified for each fault (FMEA – Failure Mode and Effects Analysis);

Identification of mitigation strategies and recommendations to reduce or prevent the occurrence of identified failures;

Quantification of a failure rate for the machine’s critical components;

Reliability evaluation of the machine.

Achieved results

The study carried out by NIER achieved the following goals:

- A “Systems Engineering” method and approach for the design of automatic machines was transferred to the client;

- Information and documentation relating to the case study machine was reorganised and expanded;

- Operational criticalities of the case study automatic machine were identified and possible countermeasures and recommendations were defined with the aim of increasing its reliability performance.