Reliability analysis of the Bologna railway station signaling system

Brief

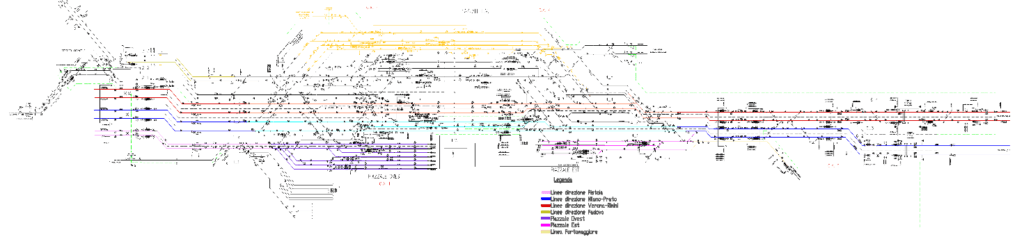

Assess RAM performance of the Bologna station signalling system, including the auxiliary systems (for data communication, power supply of equipment and air conditioning of cabinets and rooms), in order to identify any criticalities, propose improvements, and verify in advance the achievement of contractual obligations.

Verify proper performance in terms of system engineering, configuration and installation, performing field tests where necessary.

Project challenge

A complex system-level RAM analysis was required, in terms of physical devices and operations.

RAM analysis of auxiliary installations (data communication, power supply and air conditioning) and their integration into the system reliability model.

Execution of field tests to verify the correct installation and configuration of the system.

Solution

The structural adequacy of the signalling system and the auxiliary systems was verified by qualitatively analysing the failure conditions of the equipment and quantitatively estimating the reliability and availability performance of the individual functions implemented.

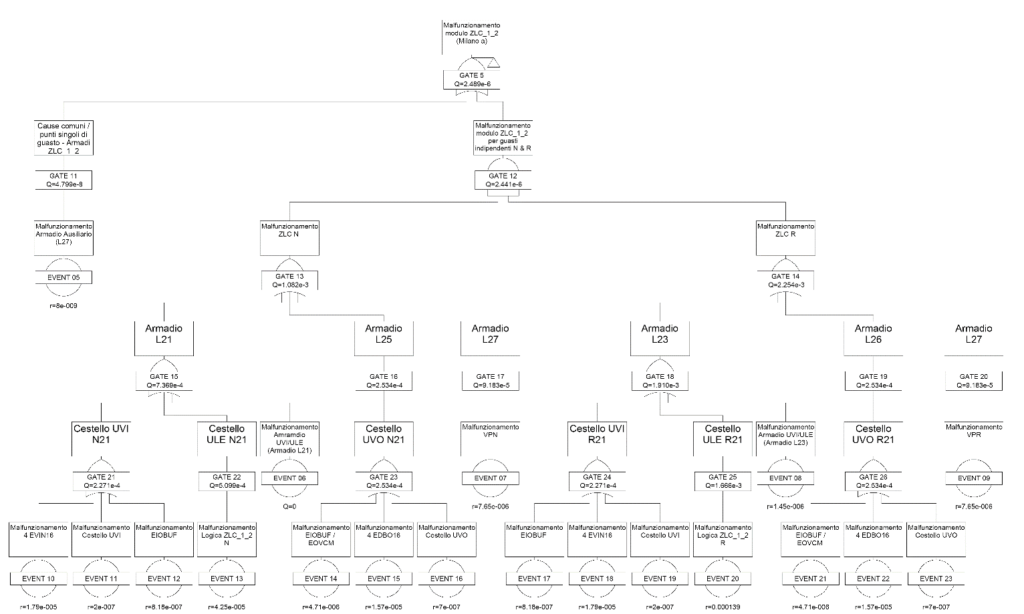

The analysis of equipment failure conditions and the related effects on system functionality was carried out using FMEA methodology.

The equipment reliability characteristics (failure rates) were estimated from records of failures occurring during the operation of similar systems, under comparable operating and environmental conditions. The equipment maintainability characteristics were assessed with reference to the engineering characteristics established for the specific application at Bologna station.

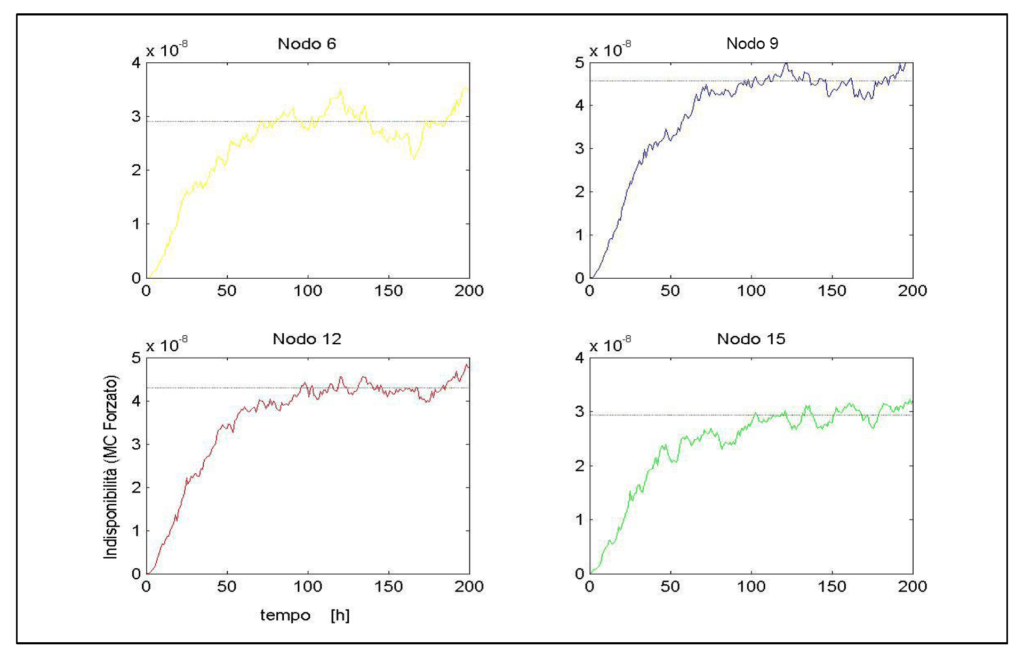

The reliability and availability performance of the signalling and auxiliary systems was assessed by means of reliability block diagrams, fault trees, event trees, Markov chains, Monte Carlo simulations with cellular automata variance reduction. The results enabled predictive verification of the fulfilment of contractual RAM requirements.

Adequate engineering of the system was verified by taking into account the actual allocation of the circuit boards (board location within the racks and location of the racks themselves in the cabinets), the actual connections between the control equipment and the yard equipment and the position of the latter with respect to the station’s entrance and exit lines. To this end, a specific Dependent Failure Analysis (to identify single points of failure and common causes of failure) and a qualitative assessment of human reliability (to identify failure modes) were carried out. On the basis of the results obtained, the infrastructure unavailability scenarios were defined; the probability of occurrence of each scenario was assessed starting from the reliability and maintainability characteristics estimated for the individual equipment and auxiliary systems (to complete the assessments strictly necessary to verify compliance with the requirements).

The proper configuration and installation of the equipment was verified with reference to the degraded operating modes of the system. In particular, field tests were carried out to verify the appropriate management of (single) fault conditions of the equipment (installed in a redundant configuration).

Execution phases

Analysis of (single) fault conditions of the signalling and auxiliary systems.

Probabilistic equipment modelling.

Estimation of the reliability and availability performance of the system and verification that the applicable requirements are met.

- Identification of infrastructure unavailability scenarios by means of dependent failure analysis and qualitative assessment of human reliability.

Implementation of field tests for the functional verification of degraded operating modes.

Achieved results