Industrial energy diagnosis for chemical companies

Brief

Fulfil the energy audit obligation required by Italian Legislative Decree 102/2014 for large and energy-intensive companies and identify energy efficiency solutions.

Project challenge

to adopt of a group approach for the fulfilment of the energy audit obligation, including about 20 companies characterised by a diversity of activities. Drafting of energy audit reports, with identification of opportunities for improvement, for complex production plants that are already heavily controlled and managed with a view to maximum efficiency.

Solution

An innovative system architecture was defined, overcoming the classic “site by site” approach and opting for a more centralised management solution that would enhance the skills and responsibilities of the company’s Energy Management Unit.

Execution phases

Collection of energy consumption data from approximately 40 sites belonging to the 20 Group companies.

Selection of 4 sites to be subjected to an energy audit by means of a single industrial clustering plan at Group level.

Kick-off meeting to share the material needed for planning and carrying out technical inspections.

Data collection relating to:

- characteristics of energy-intensive plant/equipment;

- description of company energy flows;

- monthly consumption of electricity and methane gas for the previous three years (billing data and measurements from existing monitoring systems).

Detailed technical inspections to survey the existing installations by means of a census of the individual electrical and thermal users.

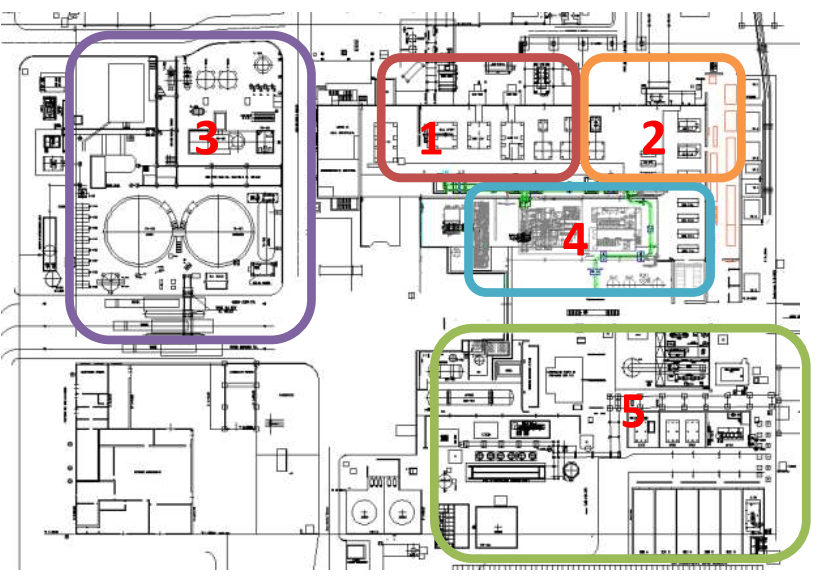

Electrical and thermal modelling of the plant and calibration of the models on the basis of actual consumption data to identify the most significant energy-intensive areas.

Identification of energy performance indicators, also for the possible subsequent implementation of an Energy Management System in accordance with the ISO 50001 standard.

Drafting of 4 energy audit reports, in accordance with CEI UNI EN 16247 parts 1 to 3, with identification of possible energy efficiency measures and their quantitative economic evaluation.

Upload of the documentation to the dedicated ENEA portal.

Achieved results

operational and technical measures for energy efficiency were identified corresponding to a total of 900 toe of energy savings, thus achieving full regulatory compliance.