Process innovation for the sustainable ceramic tile supply chain

Brief

IPERCER – POR-FESR Emilia Romagna 2014-2020.

Identify the best energy efficiency techniques related to the different stages of the process and production facilities; develop a platform for constant and detailed monitoring of the energy performance of the facilities, to be used as part of a continuous improvement cycle.

Project challenge

to determine energy performance indicators attributable to firing and post-firing processes, aimed at proper energy management and the definition of process efficiency measures, with particular attention to the production of large slabs, through an experimental survey of processes.

Solution

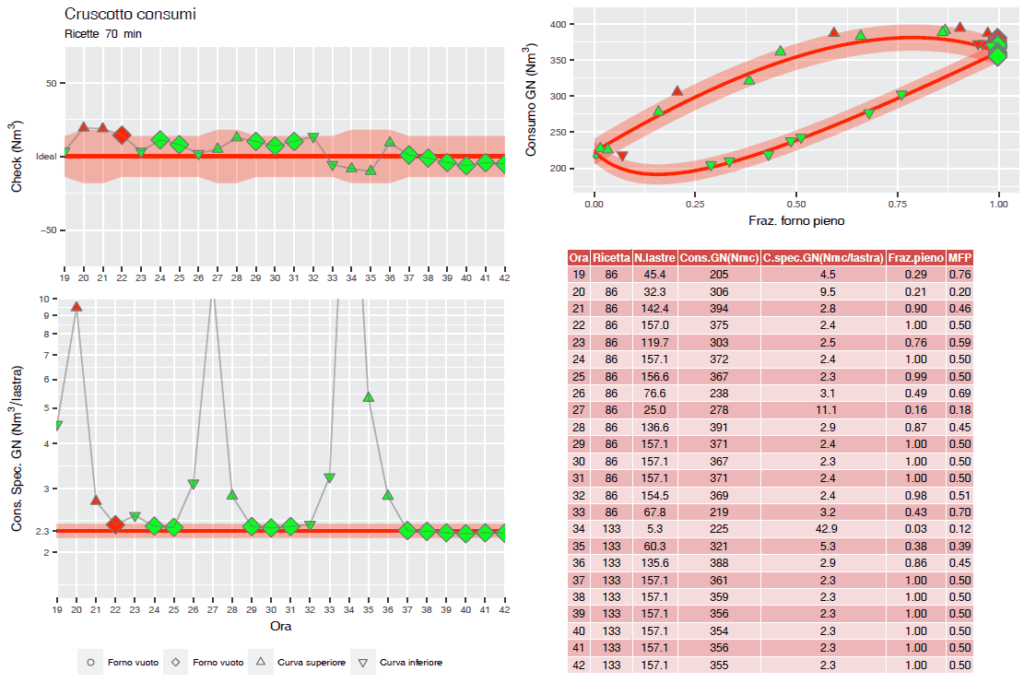

development of statistical regression models, determined by the relationship between natural gas and electricity consumption and the parameters of the firing and post-firing processes; provision of a useful dashboard for continuous energy monitoring of the firing plant.

Execution phases

Bibliographic research and interviews with plant manufacturers on BAT (Best Available Techniques) related to energy efficiency in the ceramic production sector.

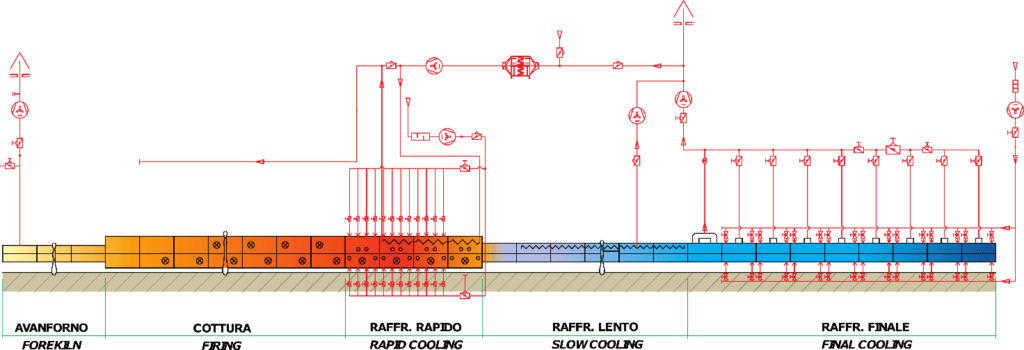

Energy analysis of the firing and post-firing systems of an industrial partner engaged in the research project.

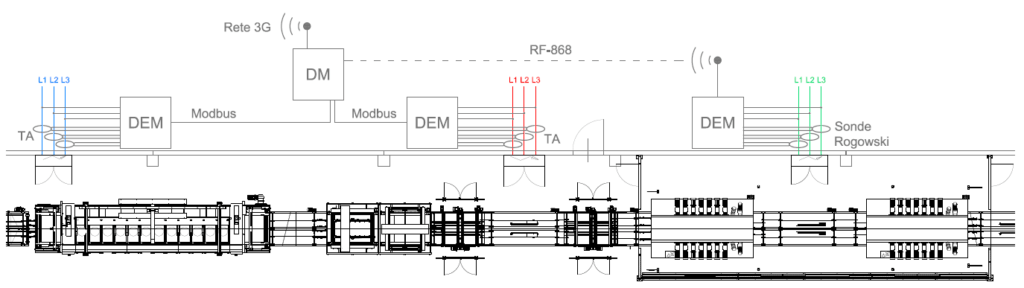

Installation of an electrical consumption measurement system on the lapping, cutting and grinding sections of the partner’s slabs in the project and survey of process parameters in the field.

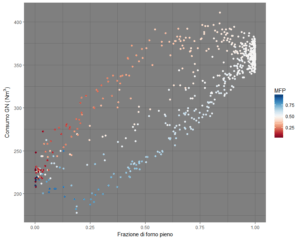

Multivariate statistical analysis of the conduction data of the slab firing kiln and determination of the process guiding factors.

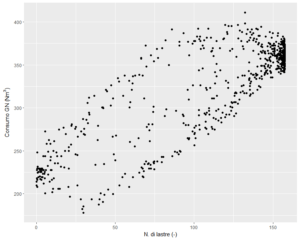

Analysis of the natural gas consumption data of the kiln and of the electricity consumption of the post-firing processing lines; determination of the consumption baseline

Determination of regression models linking consumption and process parameters.

Development of a dashboard for the energy monitoring of the firing kiln.

Achieved results

the analysis of the data relating to the firing of the large slabs and the subsequent post-firing processes led to the definition of the consumption baseline, through the determination of statistical regressions involving some process parameters; the Energy Performance Indicators (EnPIs) obtained from this analysis can be used in an energy monitoring system for the processes, as shown in the dashboard developed for the control of the firing kiln.