EC UL Engineering Analysis and Stress Assessment

Brief

Validate the design of the Electron Cyclotron Upper Launcher Port Plug of the ITER fusion reactor in preparation for the Final Design Review, in accordance with the applicable nuclear design codes (RCC-MR), taking into account all loading conditions associated with the normal operation and the envisaged accidental and incidental scenarios.

Project challenge

- Complexity of the Port Plug geometry and consequent numerical models.

- Heterogeneity of loading conditions, to be considered individually and in combination, according to the reference scenarios.

- The need for MultiPhysics simulations for thermo-structural analysis of the Port-plug under applicable thermal, mechanical and electromagnetic loads.

- The need to verify the structural integrity of the Port Plug by applying equipment construction codes for nuclear installations.

- Continuous support for the Port Plug design effort through subsequent analysis iterations.

Solution

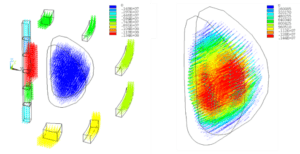

- Simulations of transient electromagnetic events were developed to calculate the currents induced by plasma disruption events and the resulting Lorentz forces acting on metal structures.

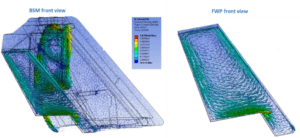

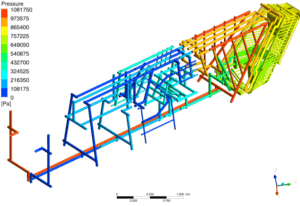

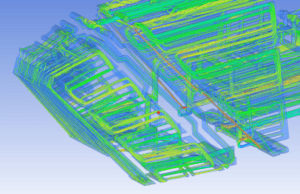

- Fluid-dynamic simulations of the CFD refrigerant flow within the cooling circuit were developed in order to evaluate pressure losses and velocity distributions.

- Thermo-fluid dynamics (CFD) simulations were developed in order to evaluate the temperature distribution due to the applicable thermal sources: radiation from the plasma, stray radiation associated with the EC UL Port plug functionality (energy injection into the plasma), volumetric heat flux from nuclear radiation, and cooling fluid. The thermo-fluid-dynamic analyses were performed allowing for conjugate heat transfer issues. Turbulence was modelled using RANS-type models.

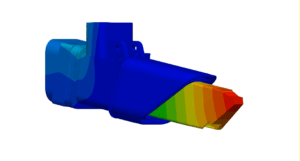

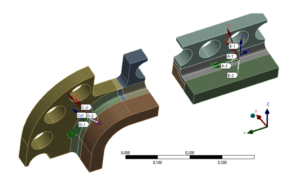

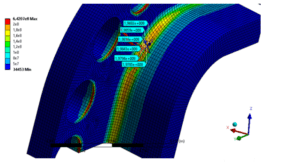

- Static and transient structural analyses were used to develop numerical simulations of the structural behaviour of the Port Plug under dynamic loads of a seismic nature and due to plasma instabilities. Modal analyses and structural, static and dynamic analyses were carried out by means of appropriately developed and validated finite element models (FEM).

- The results of the analyses (stress and displacement distributions) were used to verify the structural integrity of the system, using the rules defined by the nuclear equipment construction codes (RCC-MR, ITER-SDC-IC).

- On the basis of the results obtained from the structural analyses and verifications, specific modifications to the design of the Port Plug were proposed.

- CFD: Computational fluid dynamics

- FEM: Finite Element Method

Execution phases

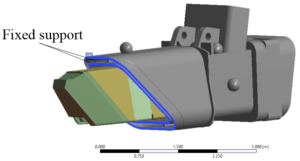

Creation of the numerical model for FEM and CFD analyses: generation of the calculation mesh, imposition of constraint and load conditions.

Execution of the analyses.

Verification of structural integrity (stress assessment) by applying the construction code rules.

Proposed changes to the Port plug project (if necessary).

Achieved results

Numerical simulations were performed using ANSYS Workbench 18.2, ANSYS Mechanical 18.2, ANSYS CFD 18.2 and ANSYS EMAG.

Finite Element Mesh

Boundary and loading conditions

Modal analysis

PF and CD current directions

Currents during VDE III event

Pressure drops assessment

Fluid velocity

Stress assessment